SQtooling

Unique Tooling Management for Procurement and Supply Chain experts

Master Tool Management

- Keep your tool related data at your finger tip

- Master Tool Management offers you:

- Tool material information

- Use of tool (for example: casting pattern, forging die, stamping tool, welding fixture, machining tools)

- Number of cavities

- Related first sample inspection reports

- Tool inspection reports from supplier

- Tool release reports

- Unique tool identification in system

- Tool identification at supplier side

- Estimated tool life management

- Investments in tooling

- Upload, edit and delete tools

- Tools are corelated with part numbers and revision status of part

Tool Revision Management

- Many times supplier makes tool corrections and modifications which are not documented and communicated to customer!

- Tool Revision Management allows you to keep track of all such actions

- SQtooling offers great support during Engineering Changes as all tool related data is available in real-time with SQtooling

- Software keeps track of all old and new revisions in tool.

- Supporting files like technical simulation output and part master 3D can be stored and accessed at ease of few clicks

Tool Life Management

- Digital management of tool life for all your supplier’s manufacturing tools

- Simple Uploading of data from current ERP-system

- Real-time tracker of tool life

- Exporting tool life data for further analysis

- Tool life tracked as per supplier and tool number

- Avoid lot of communication need via mails for tool life data

- Budgeting & CAPEX process for toolings at your suppliers needs now only couple of minutes with SQtooling

Tool Cost Planning

- SQtooling offer you to plan tool costs and budget in advance

- Tool Planning allows you now smooth introduction of new tools

- Advance intimations and warnings, offers proper cashflow management

- Tool Life and Tool Costs offer you to calculate your purchased part cost more accurately

- Supplier Comparison for same part and tooling can be made

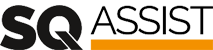

Tool History and Repairs

- Keep track of each repair made by supplier on tool

- Tool History involves change of spares, maintenance details and modifications made on tool

- Supporting documents like Inspection after repair/change and details of change are stored

- Co-relation of change and supporting documents makes decision process faster

- As customer, you have access to all real-time status of your manufacturing tools at your suppliers

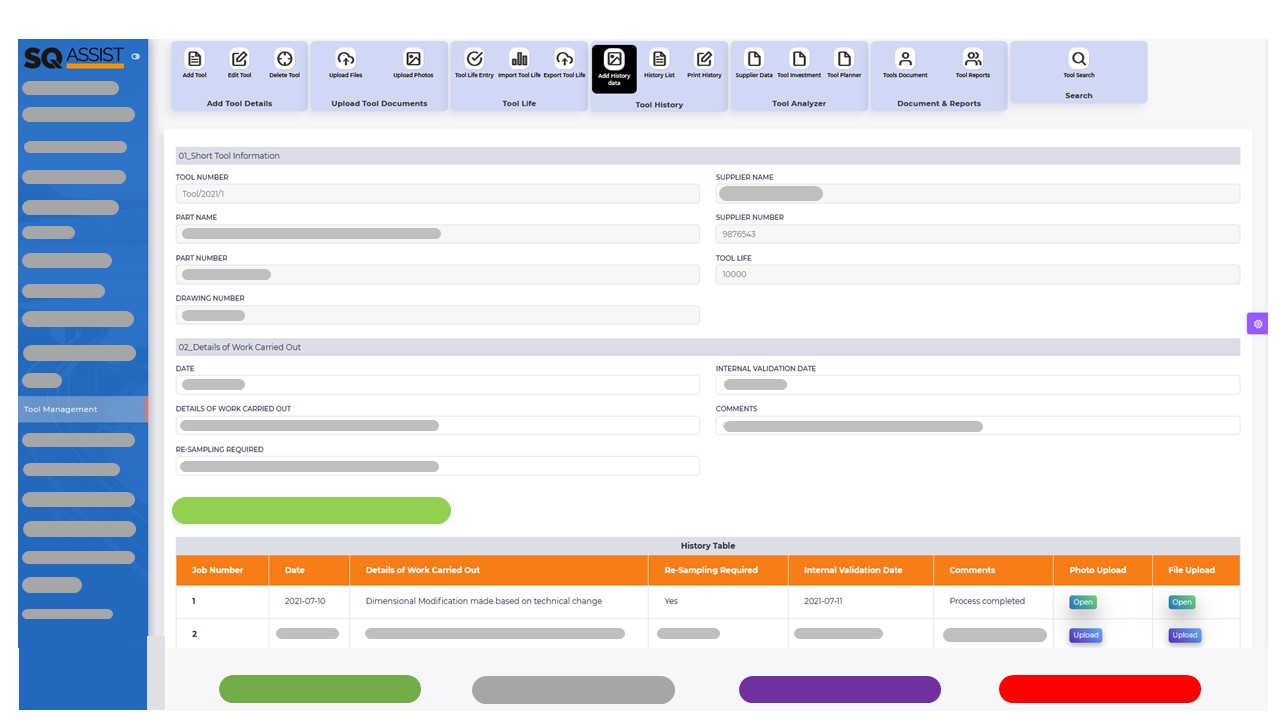

Further smart features of SQtooling

Supplier Tool Performance

Tool Document Management

Zurück

Weiter